Services

- Design charrette Civil and site improvement engineering

- Structural engineering

- Sustainable design

- Architectural design

- Mechanical, electrical, and plumbing engineering

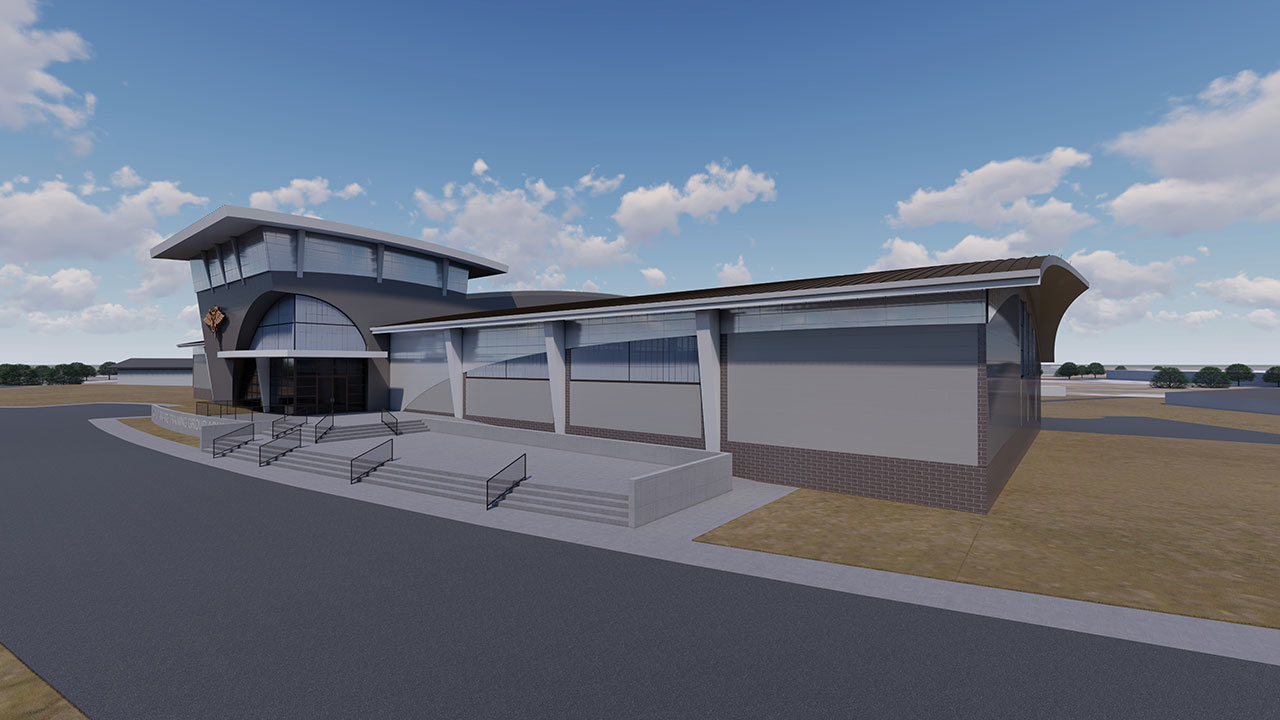

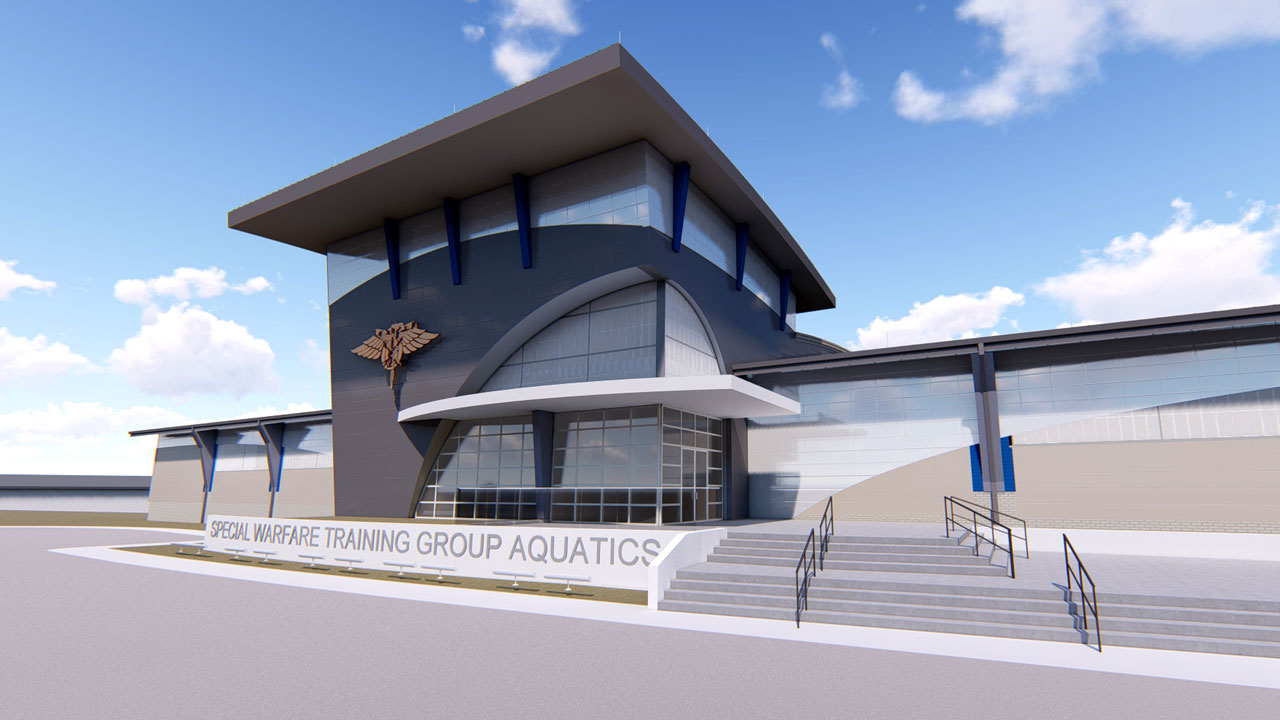

The aquatic training facility consists of two enclosed, climate-controlled, chemically balanced, temperate, ventilated, and observable water tanks of varying depths geared to meet the specific needs for training the elite warriors of the USAF. The primary training area containing the two separate aquatic tanks/natatoria provides a diversity of training environments, including both stressed and non-stressed environments, in one space.

One of the tanks is 54 meters by 25 meters with two movable bulkheads and multiple depths to accommodate the full range of training scenarios. The second tank is 52 meters by 25 meters with one movable bulkhead and multiple depths to also accommodate a full range of training scenarios.

The natatoria are separated by a central spine that provides acoustic separation and contains shared dry land training rooms; a locker room; showers; and areas for storage, training support, instructor and cadre administrative, and building systems. The facility also is divided vertically into two distinct zones. The upper level includes the public entry, all instructor and cadre offices, locker rooms, restrooms, and a briefing space, as well as instruction space for review of pre- and post-training videos and lessons. From the main observation decks, which run parallel to the training tanks, a series of catwalks provide optimal instructional and safety oversight of the training tanks. The lower level contains all trainee areas and the adjacent locker area is an open cage divided into multiple zones to meet the various class sizes.

Tetra Tech developed concept designs using interactive 3-D building information modeling (BIM). The model allowed the team to work with Joint Base San Antonio and the users to incorporate changes to the planned roofing system and building positioning, significantly lowering roofing costs, thereby helping to offset the costs of the larger building space. The team used Micro-Computer Aided Cost Estimating System (MCACES) MII Verion 4.2 software to produce the cost estimate, which considered San Antonio’s diversified economy and the resulting impact of Hurricane Harvey on the local construction market through 2021. The estimate accounts for sustainability and energy measures. The project site’s highly expansive soil conditions require the facility to have a pier-supported foundation system.

The design incorporates strategies identified by the Green Building Initiative to comply with the federal High Performance and Sustainable Building (HPSB) Requirements Guiding Principles. As part of the charrette process, Tetra Tech completed the scoresheet (in regulation with UFC 1-200-02 HPSB Requirements), identifying 27 required points such as commissioning and reducing energy use 30 percent below the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) 90.1 standards, plus additional points to be achieved during the full design phase.