Data centers—especially those built for artificial intelligence (AI) workloads—are hungry for energy, but our power grids weren’t built to handle this kind of demand.

Building power infrastructure takes time. Add in long wait times for transformers, substations, a global shortage of labor, plus the time it takes to get an air quality permit in the U.S., and you get major bottlenecks.

So, what can developers and asset owners do? Many turn to bridging power as a quick fix. It’s often expensive and dirty, but when planned into the whole energy picture, it can become a connector that scales, adapts, and pays back.

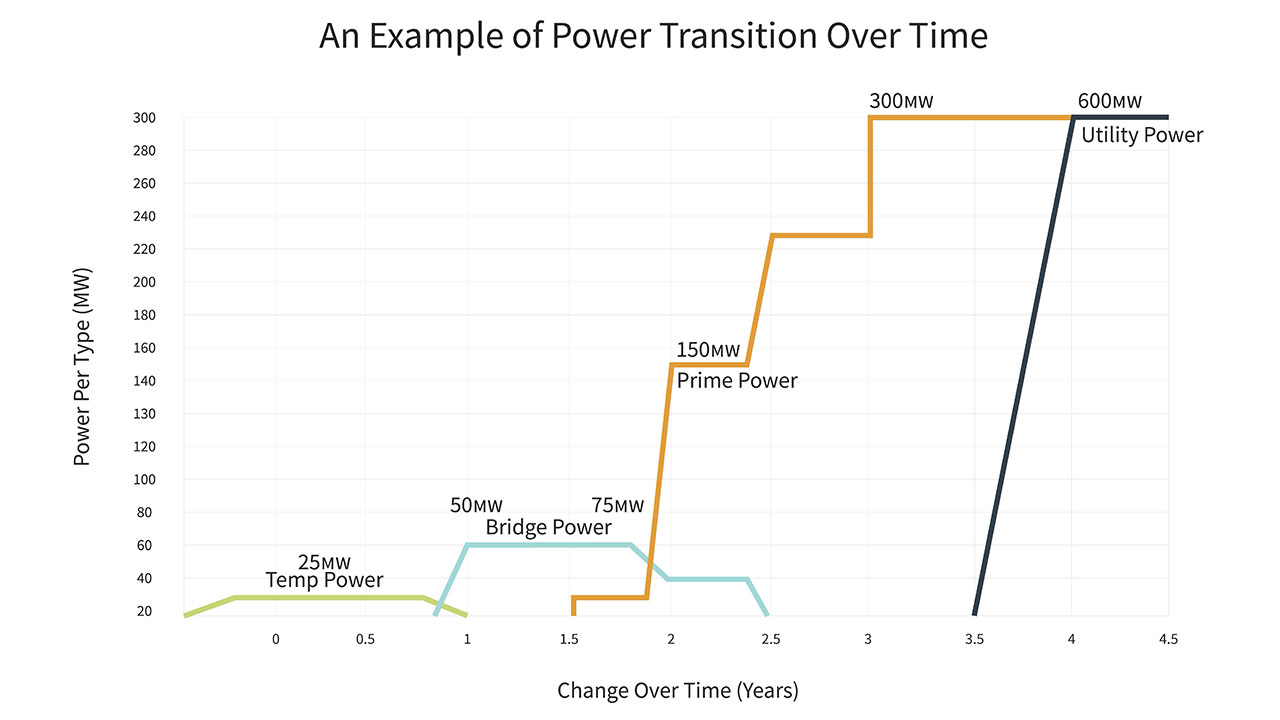

The three phases of power delivery

Most of the data center market focuses on products, which can lead to delays, stranded assets, and excessive emissions.

A more effective strategy is to focus on sequencing, scalability, and simplicity. Each phase of the power life cycle builds on the previous and will overlap due to procurement timelines, permit windows, and sequencing. You simply need a plan that connects them.

1. Temporary power (0 to 12 months)

This is fast and dispatchable, used to energize a site quickly while you wait for long-lead equipment or permits. It’s often noisy and diesel based.

2. Bridging power (6 months to 10 years)

This is where strategy comes in. Bridging power helps you keep the data center open and generating revenue while your longer-term grid or on-site solution is developed. At times, bridging power can be the prime power solution.

3. Prime power and utility partnership (more than 2 years)

This is the fully scaled end state that evolves with you. It enables your bridge to be a pathway, not a dead end. Options include:

- Utilities supplying extra capacity

- Large-scale on-site prime power system with:

- Shared maintenance from the local utility, enabling the power plant to be built to utility standards and support with operations and maintenance

- The ability to import and export power

- Nuclear

If the grid can’t deliver in the timescale you need, private on-site solutions often can. While utility upgrades might take three to five years, on-site options can be deployed faster.

We worked with a client to find alternative power solutions when their utility provider was only able to provide a minimal amount of power to their facility—a liquid-cooled AI data center. We looked at many different types of power generation options to create a power masterplan. These included low- and high-revolutions per minute (RPM) engines, turbines, linear generators, and fuel cells across varying brands and products.

Our client’s chosen solution provided 25 megawatts (MW) of temporary power in 30 days, 50 MW of bridging power at 12 months, and 300 MW of prime power at 24 months. The final stage—prime power—involved connection to their local utility provider.

Power life cycle economics

The revenue for a 25 MW data center in the U.S. makes a strong case for getting powered up fast.

| Item | Financial return |

|---|---|

| Landlord monthly revenue | $7.5 million |

| Tenant revenue: Graphical processing unit (GPU) cloud revenue lens (tenant-side, not landlord rent) | $4 to $8 per GPU-hour, 80% utilization generating $750,000 to $1.5 million per day |

| Annual rise in utility power cost | Annual rise in onsite power cost |

| Substation land take and fees – 5% escalation each year | Can land in 1 to 18 months with lower $ per kilowatt-hour (kWh) – 3% escalation each year |

| Assumptions | |

| |

Sources:

- https://www.delawarefunds.com/insights/data-centres-powering-the-growth-of-ai-and-cloud-computing

- https://www.cbre.com/insights/reports/global-data-center-trends-2025

- https://www.cbre.com/insights/books/us-real-estate-market-outlook-2025/data-centers

- https://www.jll.com/en-us/insights/market-outlook/data-center-outlook

- https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/ai-power-expanding-data-center-capacity-to-meet-growing-demand

- https://brightlio.com/data-center-stats

Understanding your power

Power isn’t just about speed. When modeling solutions, it’s important to look at the following across the power life cycle:

- Capacity and load trajectory

- On-site generation and storage capacity

- Energy bought from utilities and tariff structure

- Backup strategy and equipment offset optimizations

- Carbon emissions and sequestration strategies

- Capital expenditures (CAPEX) and financing

- Schedule for implementation

- Operating expense (OPEX), including maintenance; health and safety heat and cold labor limits; staffing; welfare; snow and heat logistics; and associated performance guarantees

- Levelized cost of delivered power

This gives you a business case to align engineering decisions with financial outcomes.

Choosing the right technology

A design team that’s product agnostic will give impartial advice on the best products for your business, free from vendor-influenced biases. This independent advice should lay out all your options, including fuel cells, reciprocating engine gensets, gas turbines, linear generators batteries, solar, microgrids, and hybrid models. Ensure you know how each option you’re presented with impacts the bigger picture and power life cycle.

Choosing a team that can capitalize on their global relationships for procurement is also a win as the best-fit products aren’t always the closest.

Sustainability

Understanding load profile is a key part of every project. It helps rightsize the infrastructure inside a facility, as well as the power utility that feeds it. This, essentially, cuts unnecessary fat out of design while still creating a compliant facility.

By adopting this performance-based engineering approach, we achieve:

- Electrical design aligned with actual power demand

- Smaller electrical feeders and services, reducing unnecessary infrastructure

- Lower capital and operational expenses

- Increased usable square footage

- Positive sustainable impact

The value of deploying responsible fuel

Non-combustion fuel technologies are both cleaner and faster to roll out. This includes fuel cells and controlled, pressurized reactions that avoid nitrogen and sulfur oxides, the pollutants that trigger long permitting timelines. In the United States, this helps streamline air quality approvals and stay under local caps. The project then bypasses Title V restrictions.

High-efficiency power isn’t compromised, it simply comes with a smaller carbon footprint. Waste heat can also be recovered from these systems to generate chilled water. This means less strain on mechanical systems and a smarter approach to cooling in high-density AI racks.

Where possible, choose fuel that improves efficiency and gets you closer to net zero emissions.

- Go for non-combustion gas pathways, such as fuel cells with controlled pressurized reaction.

- Invest in efficiency up front to save on fuel cost.

- Use waste heat by channelling heat recovery into chillers to keep water use low (air-cooled heat rejection and closed-loop liquid-to-chip).

- Consider on-site solutions. When you have sufficient redundancy (N+3 or N+4), you can eliminate diesel standby entirely and shift utility power supply CAPEX cost into a different entity, saving on CAPEX, OPEX and land.

- Proactively report to track emissions. This helps ensure plant is operating how it was designed.

Data center power is a complex problem. We make it simple.

Power planning involves many moving parts. Modeling different power scenarios can reveal site-specific energy limits before you commit.

The fundamentals of power masterplanning

Business vision: this should include load profile and use, tenant specification, anticipated lease rate $/kW/month, speed to power, go-live, and optimal project phasing.

Technology shortlist: one that covers each product’s impact on OPEX, space, and schedule.

Independent vendor evaluation: a product-agnostic approach opens the door to choosing equipment based on what’s best for your site, timeline, and long-term goals.

Financial analysis and planning: CAPEX; engineering, procurement, and construction (EPC); OPEX; levelized cost of energy $/kWh (LCOE); internal rate of return (IRR); equipment offset; net present value; funding strategies; and cost of data center $/MW versus cost of power plant.

Site selection: space required for power generation; utility capacity and costs over time; tariffs and demand charges; outage history; air limits by site; soils, flood, and natural hazards; fuel costs and escalation; land pricing, permits, and regulation; labor availability and limitations; and more.

Design integration: the on-site plant works must operate with data hall design, ideally with a performance-based engineering approach as a key part of the design.

Commissioning and ongoing reporting: this stage closes the loop with actual use and load profile analysis, providing real data to inform your next phase.

Designing for uncertainty

No power master plan will stay locked in until final roll out. Your energy use will grow, fuel availability will change, and regulations will tighten.

AI loads don’t behave like traditional enterprise IT. Load variability, heat output, and redundancy requirements all need smart responses. A well-sequenced master plan keeps you agile, enabling the flexibility to:

- Add capacity over time

- Switch fuel

- Align with grid upgrades

- Eliminate fossil fuels

- Track performance and emissions across the asset’s life

The power feedback loop

It’s also critical to build in a power feedback loop for distinct phases, for example now, next, and later. This gives you an opportunity to:

- Negotiate gas costs over expected growth

- Revisit the mix as markets and regulations shift

- Keep an eye on future prime options in the long-term model

Future-ready power

In our view, the optimum way to plan a data center, or enable greater capacity in one you already own, is to treat power as a lifecycle, not a checklist. This strategic approach ties power into CAPEX, OPEX, and return on investment. It can also:

- Simplify the process

- Get you online faster

- Reduce emissions

- Keep costs predictable

- Leave the door open for what’s next

When it’s done right, temporary and bridging power don’t just heat the chips, they form steps in an agile plan that establishes power security, scalability, and resilience.

Connect with us. Reach out to our experts in data center solutions.