According to the U.S. Environmental Protection Agency’s Landfill Methane Outreach Program, municipal solid waste (MSW) landfills are the third-largest human-generated source of methane emissions in the United States. That makes reducing methane emissions from MSW landfills through landfill gas (LFG) management one of the best ways to reduce the overall CO2e emissions potential, a key factor driving federal New Source Performance Standards.

Owners who are already controlling LFG would do well to use it as a resource. Developing an LFG beneficial-use facility does just that. Such a facility can protect the environment and improve human health while offsetting rising operating costs and generating revenue. It is critical for owners to take the right steps to minimize costs and maximize revenue when developing a facility. They can begin by considering the following factors.

Structure wellfield components to ensure reliability

LFG extraction systems are, in a sense, giant vacuums that carefully and meticulously pull the constantly generated methane from the waste mass. Therefore, the design of an extraction system must factor in the landfill’s size, location, climate impacts, and access to infrastructure and utilities. For an underground system, components must be sized and constructed to provide the owner with assurance of reliability.

Strive for optimal collector spacing

Vertical and horizontal collectors are the most prevalent means for extracting LFG from the waste mass. General guidance for these components includes keeping spacing optimal to help lower the applied vacuum, minimize ambient air intrusion, and provide redundancy during LFG collection. Optimal spacing is generally considered to be the best technical assessment of the subsurface stratigraphy, considering general trash makeup, compaction, soil type, intermediate cover components, and volume of liquid in the landfill. Tighter well spacing generally provides a higher quality LFG flow with less stress on the wellfield.

Consider operating considerations for recovery projects

Just like the design, the operation of the system is important in maximizing the effectiveness of the beneficial-use of LFG. Monitoring and balancing the gas extraction system is relatively simple when done properly. The art of wellfield tuning is the key to effective gas system operation. Each gas extraction well is one actor in a well-choreographed play. When each well is viewed as a critical component to the overall system, the concept of one affecting the whole becomes easier to understand. Adjustments to one well can have an impact on the entire system, requiring patience and perseverance to achieve your goals. For a beneficial-use project, the considerations during operation are:

- Optimize fuel recovery

- More flow at existing gas quality

- Better gas quality at existing flow rate

- Reduce air intrusion

- Increase methane content

- Recover more gas sooner with interim collection

Start the journey with good data

Data is the key to a successful project, regardless of size. Analyses and evaluation of trends help identify issues that may not have been evident during design. Just scanning the surface and landfill topography may not give you the complete picture. Even when your data points to something potentially catastrophic, that trend may help you find a workable solution and, possibly, salvage a bad situation.

While reviewing data collected from the wellfield, seeing data trends is critical and will guide owners towards more effective operations. Looking back over the past several months or past year to assess changes can help account for seasonal changes.

Factor in the age of your LFG system

The age of your gas collection and control system (GCCS) can also have an impact on operations. Older portions of the system often can be buried quite deeply as additional waste materials are placed. Over time this may lead to differential settlement of the header or structural deformation/failure. Older system components may be undersized for current and future operations—temporary headers have a way of becoming permanent and expansion of the waste footprint moves the operational goal posts, oftentimes beyond what the original GCCS components are capable of handling. The expansion of the waste mass also can create wells with excessive lengths of solid casing. Wells should be evaluated for both structural integrity and the relative length of available perforated casing to determine whether they should be redrilled.

Strategies for effective LFG extraction and liquid management

Liquids are necessary to circulate nutrients and bacteria for decomposition. However, too much liquid in the landfill can inhibit the ability to effectively remove the LFG produced. The liquid levels within the well casings should be routinely checked and pumps installed as needed to optimize the perforated casing’s availability. The relative volume of liquids pumped and the impact of removal on both liquid levels and LFG flow should be evaluated to review the net benefits.

Plan for utilization facility development

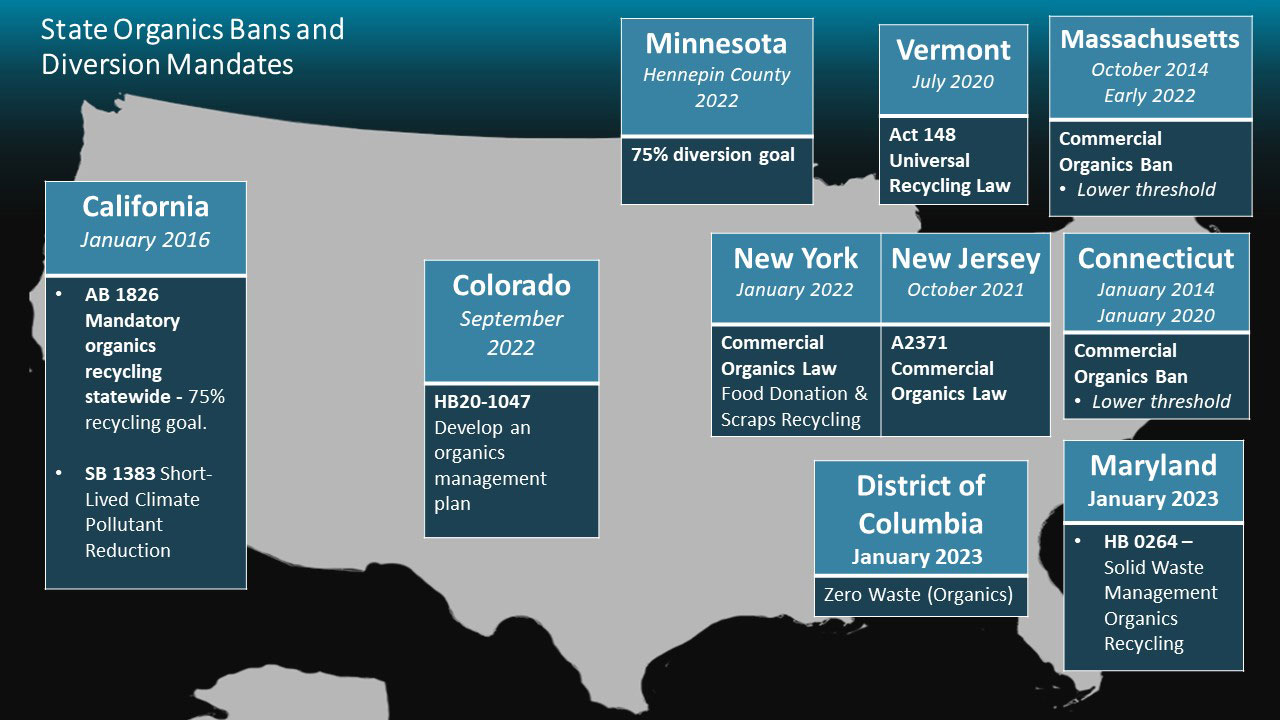

If a landfill owner sets up their own anaerobic digestion (AD) or composting operation to comply with organics diversion regulations (coming soon to a state near you!), then they get to keep the food waste intake and revenue they now have. This enables them to open new markets and waste streams for disposal. Keep in mind, setting up your own AD will reduce LFG generation from the landfill, due to the lower rate of organic intake, but will provide another source of high-quality biogas from the AD.

When setting up an AD, you need to account for:

- Odors—different odors, but odors nonetheless

- Waste liquids

- Equipment and truck traffic

- Unpackaging facilities

- Potential for high-quality biogas from AD

Assess and identify potential impediments to developing a successful LFG project

Developers should employ mechanisms to assess, identify, and mitigate the various potential pitfalls in developing an LFG beneficial-use facility. Knowing the right questions to ask is the first step in developing a successful project. Be sure to consider the impacts of pending organics diversion legislation and the relative difficulties with developing utility interconnects.

About the authors

Tom Bilgri

Tom Bilgri, manages Tetra Tech’s Biogas Engineering Services group.

He has more than 30 years of experience in LFG management system engineering and has worked on developing beneficial-use projects, including direct sale, electrical generation, and compressed natural gas production facilities. He chairs the LFG/Biogas Technical Division Program Committee of the Solid Waste Association of North America.

David Knapp

David Knapp works with Tetra Tech’s Solid Waste Solutions group to grow, develop, and manage projects in Georgia and throughout the Southeastern United States.

He specializes in LFG management, utilization, and compliance. In addition, he serves as program manager and technical leader for various aspects of LFG to energy construction management and environmental service markets, including design oversight and review, due diligence, environmental support, municipal, and major solid waste initiatives with public and private clients.